What is Lean Six Sigma?

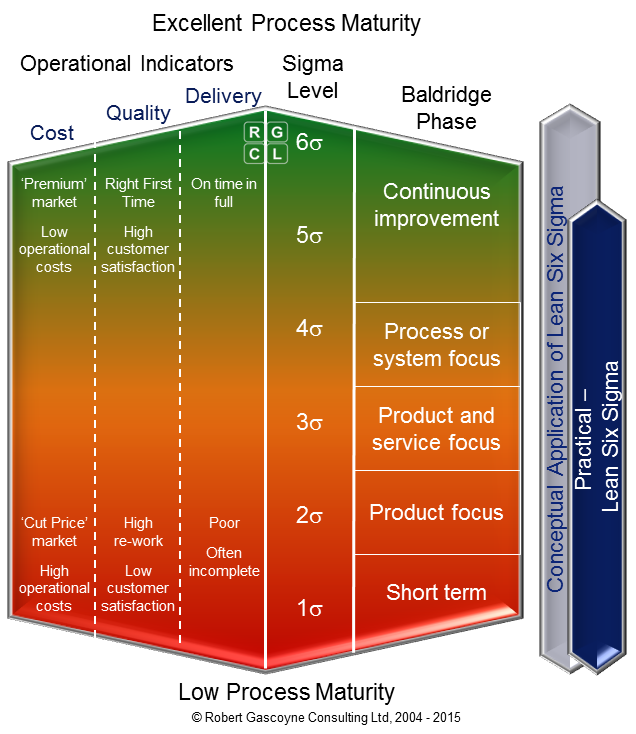

- Lean Six Sigma is a combination of the Lean and Six Sigma DMAIC methodologies

- Lean is a philosophy that is focussed on eliminating waste. Considering that only a very small proportion of we do really adds value (the rest is waste), Lean can have a massive impact. It is particularly effective at improving poor to moderate business processes

- The DMAIC methodology is a very powerful and effective methodology for improving moderately performing products, services and processes to ‘Six Sigma’ level

- Six Sigma derives it’s name from it’s statistical performance target, which equates to 99.99966% good (or just 3.4 PPM defects)

- Six Sigma achieves these incredible quality levels by:

- Focussing on customer alignment of functions, features and processes

- On establishing clear linkages to customer goals, variation from the goals is identified (ie. waste)

- Causes are identified, prioritised and eliminated and/or controlled

- The result is virtually defect free parts, products, services and processes

- This broad approach means that it can be applied to all environments and all levels

- Both Lean and Six Sigma are ‘heavyweight’ methodologies, so it’s not surprising that the combined ‘Lean Six Sigma’ is also a ‘heavyweight’ methodology, requiring a high level of training, coaching and support to become proficient

- Like conventional Six Sigma, Lean Six Sigma practitioners are generally known as ‘Green Belts’ and ’Black Belts’ . They are coached by ‘Master Black Belts’ and supported by management ‘Champions’

- The personal development and subsequent career progression of Six Sigma practitioners is usually linked to becoming ‘certified’ at each level. Certification is dependant on having met a set of stringent, pre-defined criteria, including: education, experience, and proof of results through deploying the Lean Six Sigma methodology and tools

Why we get results

- We have substantial experience in training, coaching and deploying Lean Six Sigma

- We can help you specify the best approach for your business (see Diagnostics for more details), or simply provide whatever consultancy, training and coaching or development you require

- We’re practical and pragmatic - our focus is always on getting results (we’re practitioners - not just trainers!)

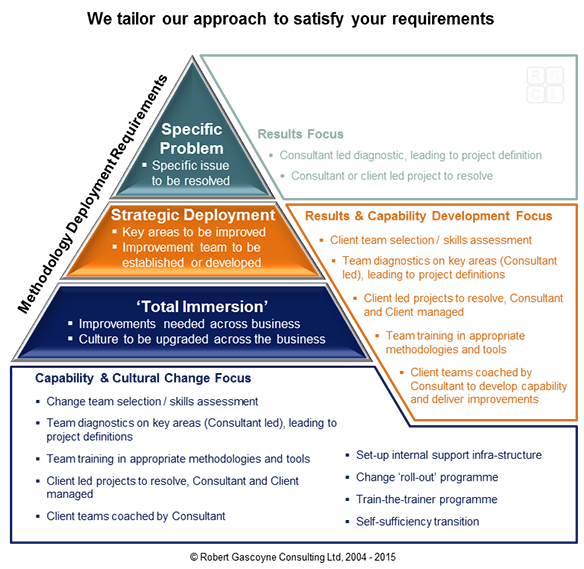

- We tailor our services and approach to meet your needs (please see methodology deployment requirements diagram below)

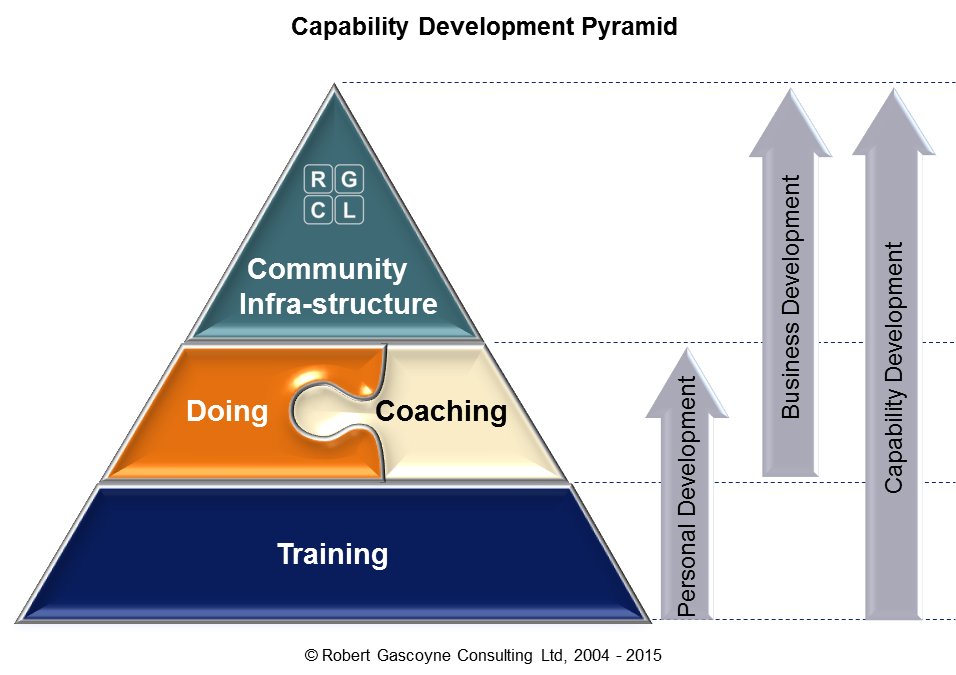

There are three basic levels to deploy any methodology:

- At a basic level a methodology can be used to solve a specific problem

- Methodologies can also be deployed strategically to resolve strategic issues across the business. Generally, this involves developing capability within the business to achieve this

- Often, businesses decide to apply a uniform approach to business improvement across their entire business. This, ‘total immersion’ approach, involves developing a ‘critical mass’ of capability within the company, with support structures to ensure that it is self-sustaining

- We can help you, whatever deployment model you choose - please contact us to discuss your requirements

Capability Development

The level of capability development is an important factor in Strategic and ‘Total Immersion’ deployments

- Training provides knowledge, but real understanding is only developed by doing

- We offer a range of coaching services, to guide capability development and ensure that results are achieved.

- Beyond having people that can do, you’ll need your own, sustainable, support structure to ensure the continued growth and success of your capability - we’ll help you create, or develop, your infra-structure to achieve this

Training, Coaching & Support

Besides full deployments, we also offer the individual components, to support and supplement existing programmes:

- Six Sigma training: bespoke and ‘off-the-shelf’ Lean Six Sigma courses available:

- Awareness

- Champion

- Green Belt

- Black Belt

- Master Black Belt, including 'train the trainer'

- For more general information about training please click [Link to Training page]

- Lean Six Sigma coaching:

- A range bespoke of support options to ensure that both personal capability and business results are achieved. These range from providing a full-time support team to remote support options, as appropriate

- Coaching is especially important for Six Sigma, as it is a ‘heavy-weight’ methodology and can be abstract for anyone not familiar with statistical analysis. It is therefore essential to safeguard your investment in training by ensuring that the trainees have adequate support during their early projects

- For more general information about coaching please click [Link to Coaching page]

- Accreditation (certification) of Lean Six Sigma professionals requires that they have proven their skills and understanding by successfully delivering projects using the methodology

- We provide certification at all levels

- When you have sufficient internal capability, we can also design, develop and install your own corporate certification process, ensuring that the capability you're developing continues to meet the real needs of your business.

- Lean Six Sigma community infra-structure: Bespoke services to design, develop and install appropriate capability support and development infra-structure.

Lean Six Sigma can can radically transform you business - eliminating waste and optimising critical processes

Please contact us to discuss your requirements

Next Steps

We’d be glad to provide more details, or discuss your requirements with you. Please contact us

Related Tools, Techniques & Methodologies

We offer consultancy (diagnostics, project definition, projects, deployments, training and coaching in the following Lean Six Sigma related tools, techniques and methodologies:

Basic Lean Concepts

- Value Add / Non-Value Add (VA / NVA)

- Taiichi Ohno’s 7 Wastes (Muda)

- TAKT time

- Deming Cycle

- Just In Time (JIT)

- Kanban

- Go to the workplace (Gemba)

- Kaizen & Kaizen Blitz (Kaikaku)

- 5S

- Mistake Proofing (Poka Yoke, Poke Yoke)

- Single Minute Exchange of Dies (SMED)

- Cost of Quality (CoQ, CoPQ)

Advanced Lean Concepts

- Goldratt - Theory of Constraints & Bottlenecks

- Level Scheduling (Heijunka)

- Runners, Repeaters and Strangers

- Autonomation (Jidoka)

- Agile Design and Manufacture (Mass customisation, late point differentiation)

- Supply Chain Flexibility Mapping (P-time studies)

- Zero Defect Manufacture (ZDM) / Zero Quality Control (ZQC)

- Cellular Manufacture, Group Technology & Flexible Manufacturing

- Moments of Truth (MoT)

- Product Design Tools – see Design for Six Sigma (DFSS section, and Design tools & techniques page

Basic Quality Tools

- Pareto Analysis

- Cause & Effect Diagrams (Fishbone, Ishikawa)

- Concentration Diagrams (Measles chart)

- Check Sheets

- Five Whys

- Affinity Diagrams

Mapping Tools

- Spaghetti Diagrams

- Process Chart

- Flowcharting

- Process Maps

- Spaghetti Diagrams

- SIPOC

Further Quality Tools

- FMEA Overview

- Process FMEA

- QFD (Basic, 4 Houses of Quality)

- Mistake/Error Proofing (Poka Yoke)

- Cost of Poor Quality (CoQ, CoPQ)

Graphical Data Analysis

- Histograms

- Boxplots

- Run charts (Time series plots)

- Scatter diagrams

- Multi-Vari Charts

- Main Effects Plots

- Interaction charts

Process Control

- Standard Operating Procedures (SOP)

- Out of Control Action Plans (OCAP)

- Gauge control plans

- Control Plans & planning

Basic Statistical Tools

- Basic Statistics

- Introduction to Statistical Process Control (SPC)

- Statistical Process Control (Run charts, Control Charts: X & R, X & s, np, p, c, u, etc)

- Process Capability (Cp, CpL, CpU, CpK, Pp, PpL, PpU, PpK, Zst, Zlt, PPM)

- Correlation

- Regression - Simple Linear

- Data Types (Continuous, Categorical, Poisson, Discrete, Count, Ordinal, Binomial, Attribute)

- Data Collection / Sampling Techniques

- See Statistical Tools page

Further Statistical Tools

- Central Limit Theorem

- Confidence Intervals

- Power and Sample size

- Regression - Non-linear (quadratic, cubic)

- Multiple Regression)

- Gauge R&R (Attribute, Continuous, Destructive)

- Process Capability - Non-normal (Binomial, Poisson, Weibull)

- CUSUM (+V mask)

- EWMA

- Transforming Non-normal Data (Box Cox, Johnson)

- Process Yield Calculation

- Span

- Stable Operations methodology

- See Statistical Tools page

Hypothesis testing

- Introduction to Hypothesis testing

- General tests for averages (1 sample Z test, 1 sample t-test, 2 sample t-test, paired t – test, t-test - 2 Sample, 1 proportion test, 2 proportion test)

- Tests for spread / dispersion (F-test, Levene’s test, Bartlett’s test)

- ANOVA (1 way, 2 way, Balanced, MANOVA, General Linear Model, General, Nested)

- Chi Square test

- Non-Parametric tests (1 sample Sign, 1 sample Wilcoxon, Kruskal-Wallis, Mann-Whitney, Moods Median test)

- Normality Testing (Andersen-Darling, Ryan-Joiner, Shapiro-Wilk, Komologorov-Smirnov)

- See Statistical Tools page

Design of Experiments (DoE)

- Introduction to DoE

- 2 Level - Linear DoE (Full, Fractional, Plackett-Burman, Blocking, main effects plots, interaction plots, etc)

- 3 Level - Non-linear DoE (CCD, Box Benkhen, Response Surface Methodology and contour plots)

- Taguchi Designs

- See Statistical Tools page

Management

- Hoshin Policy Deployment

- Management Systems

- Short Interval Control (SIC)

- Project Status Reporting

- Six Sigma Roles (Champion, GB, BB, MBB)

- Project Charter

- Critical Path Analysis

- Gantt Charts

- Network Charts

- PERT Charts

- Time Management

- Mental planning models (GRPI, TSRE, OSCA)

- Building a Financial benefits & results case

- Certification Requirements

Tactical skills

- Change Management

- Conflict Management

- Effective Meetings

- Faces of resistance

- Facilitation

- Stakeholder analysis

- Leadership

- Team building

Creative Tools

- Brainstorming

Customer Focus

- VoC

- VoB

- Identifying Customer Needs (Focus Groups, Surveys, Affinity Diagrams, etc)

- CTQ Flowdown

- Kano Model

Data Analysis

- Data Manipulation (basic, intermediate, advanced)

- Minitab™ (basic, intermediate, advanced, bespoke)

- JMP™ (basic, intermediate, advanced, bespoke)

More Tools

- See Complexity page

- See Design page

- See Product Cost Reduction page

- See Lean page

- See Kaizen page

- See Shainin page

- See TRIZ page

- Too many to list! - Contact us

Please contact us to discuss your requirements

Minitab is a trademark of Minitab Inc.

JMP is a trademark of SAS Institute